Strategic Factory Footprint

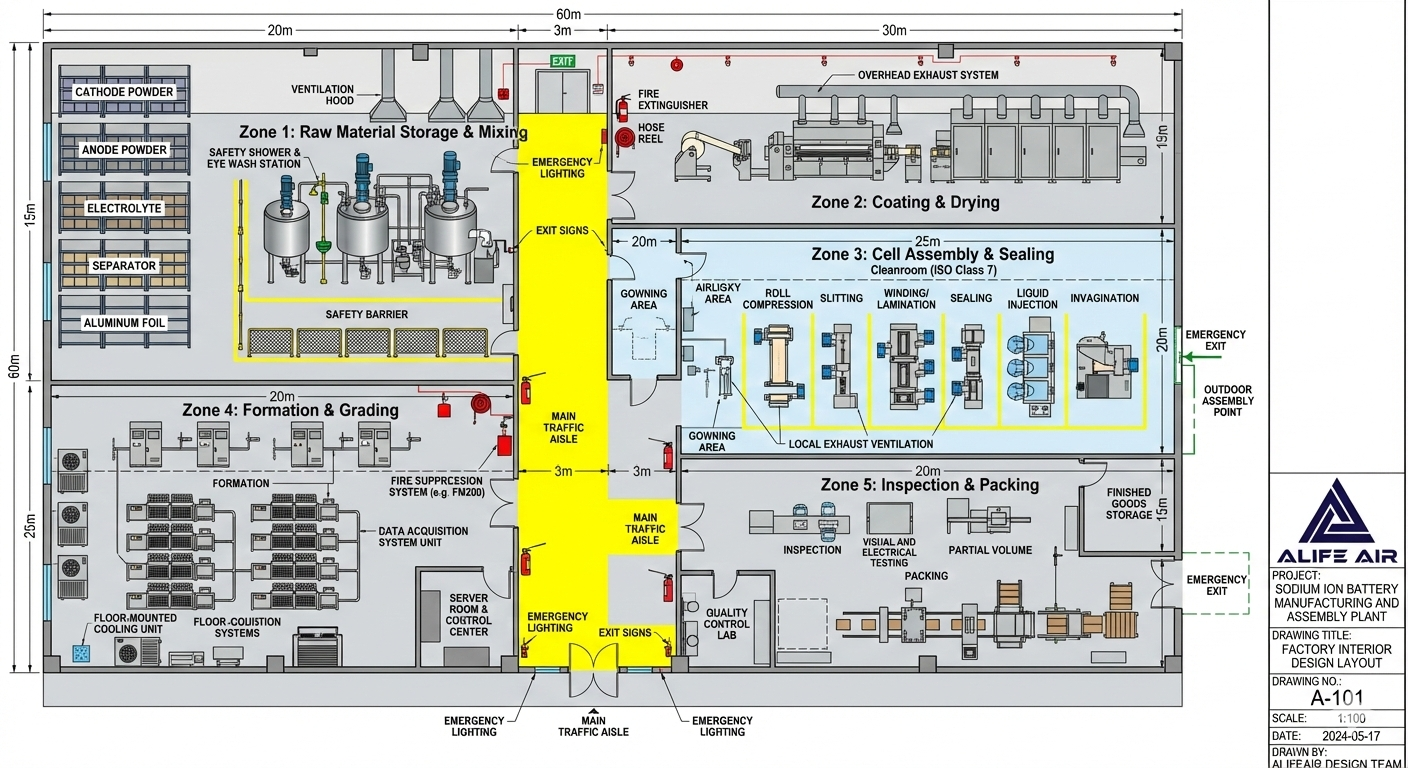

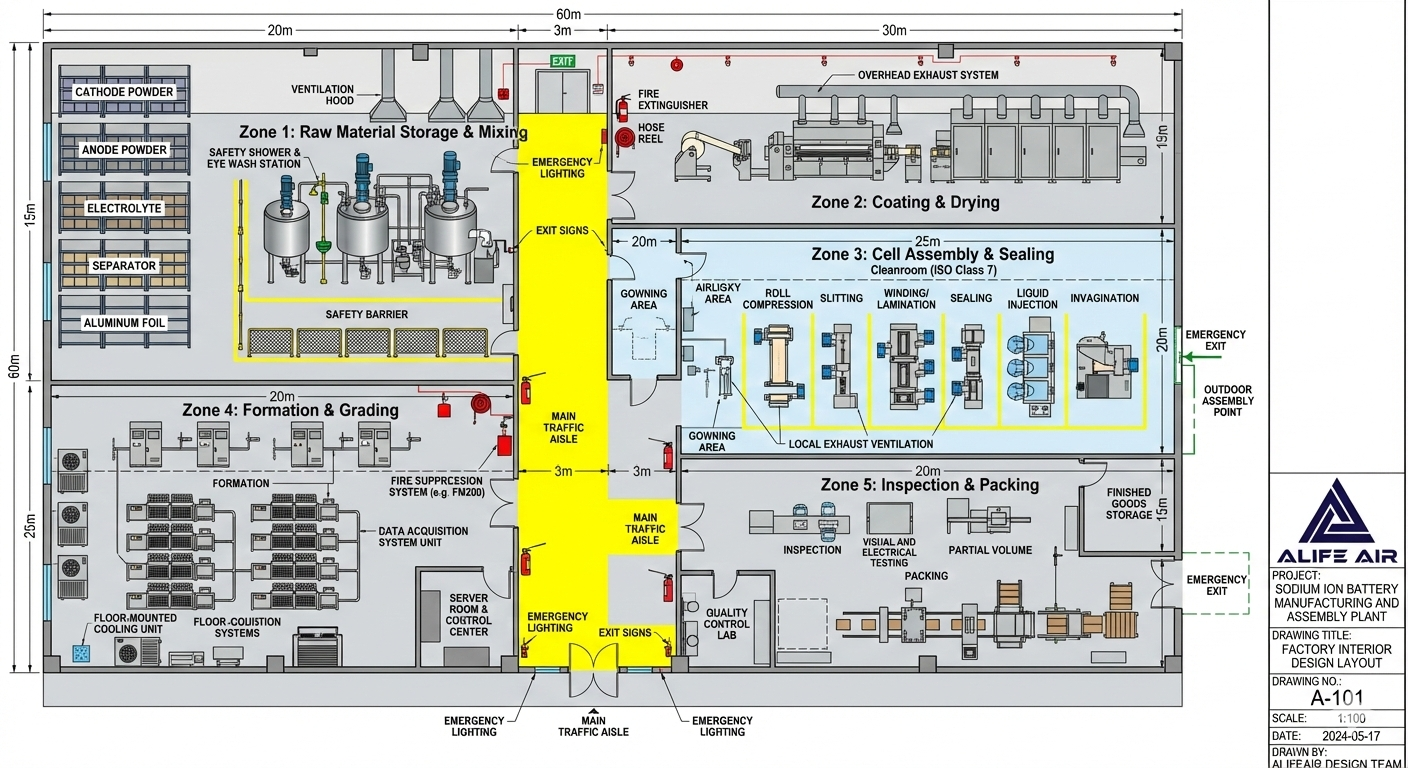

Our single-level production facility is engineered for material flow efficiency, featuring segregated manufacturing zones and controlled environmental parameters to ensure consistent Sodium-Ion cell performance.

ALIFE AIR maintains in-house 18650 cell manufacturing capability to ensure absolute cost visibility, margin protection, and operational sovereignty.

Located in Wenling City, Zhejiang Province, our facility represents a highly disciplined approach to capital deployment. By selectively acquiring and refurbishing high-quality second-hand manufacturing equipment from discontinued lithium-ion operations, we have achieved industrial-scale readiness at a fraction of the cost of greenfield new-builds.

Our single-level production facility is engineered for material flow efficiency, featuring segregated manufacturing zones and controlled environmental parameters to ensure consistent Sodium-Ion cell performance.

Process-disciplined manufacturing from slurry preparation to final outbound logistics.

Homogeneous mixing of Sodium cathode and hard carbon anode powders. Precision slurry preparation ensures electrochemical stability across production batches.

Application of active materials to current collectors. Selective refurbishment of high-grade coating lines ensures precision mass loading and uniform drying.

Single-format 18650 winding and laser sealing. Semi-automated configuration optimized for yield stability and rapid output scaling.

Systematic charge/discharge cycles to establish SEI layer stability. Grading and aging processes identify variances to ensure automotive-grade reliability.

Final EOL testing, packing, and staging for outbound shipment. Integrated traceability for all manufactured lots.

Our staffing levels are meticulously sized to support a stable monthly output of 1.9 million cells, ensuring safety compliance and predictable operating costs.

Direct operators across coating, assembly, and formation, optimized for semi-automation.

5 Quality Assurance inspectors and 4 Engineering staff maintaining equipment uptime and yield standards.

Dedicated logistics, warehousing, and management personnel overseeing lean execution.

Demonstrated manufacturability through stable domestic white-label supply relationships. Our internal production provides a ~30% cost advantage over market leaders.

Readiness for future international market participation without forward-looking commitments.

Zhejiang Industrial Base

Stable Managed Output

Singapore Relocation

IP & Branding Consolidation

Strategic Scale-Up

Export Market Readiness